Quality control assessment is of wonderful value to any kind of producer. This is the procedure of gauging, screening, determining and examining one or several item qualities as well as going even more right into comparing attained results with specific demands so that conformity is achieved each of the quality inspector. The products of evaluation can be parts that are utilized in production, ended up goods, supply or even operate in process. Importers specifically locate the assessment solutions crucial before sourcing finished products from the distributors.

The Examination Kind

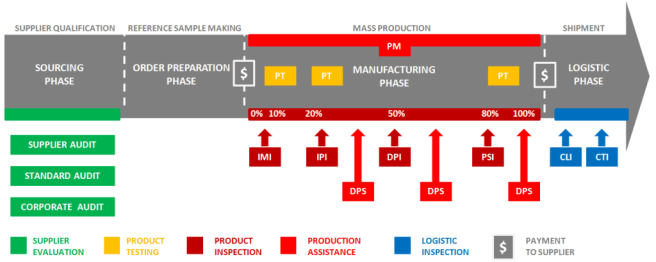

Pre-production assessment –

This is an inspection that is done prior to or during the preliminary phases of production. It can entail the evaluation of ended up items in support of the customer where samples are taken right into a lab for testing to match the offered specifications. With the outcomes, the purchaser can after that give a go in advance for the production.

Production examination –

This kind of examination can be done at various stages of product manufacturing and also to deal with any defects long before the manufacturing mores than. The production procedure is additionally complied with throughout this inspection to ensure that the health and security requirements are abided by, no minor individuals are utilized and to ensure that the regional labor laws are adhered for to the sake of securing the company and also brand. It additionally makes certain that the manufacturing will be performed in time to prevent any type of shipment delays.

Product examination –

After the product has been completed, one more assessment can take place to check for dangerous materials, heavy metals, vet medication residues and also pesticide residue in food. The food containers can likewise be checked for unsafe aspects and the odor and also preference also inspected for top quality.

Pre shipment evaluation –

This assessment happens after the manufacturing stage as well as right before the finished products are delivered to the buyers. Random sampling is done to make sure that the ideal batch sizes are shipped. It simply makes sure that the purchaser technical requirements are consulted with an authorized example.

For more information visit us:- quality control services

Loading evaluation –

This is an additional important assessment that is done throughout the packing procedure of the finished goods. It assists in guaranteeing that the packaging listing offered is followed and also makes sure that the packaging containers are in good condition to maintain damages at bay during the delivery of the items. It just is done to preserve the quality and quantity of the finished products during the shipping procedure.